JUPITER BACH POLAND PLANT

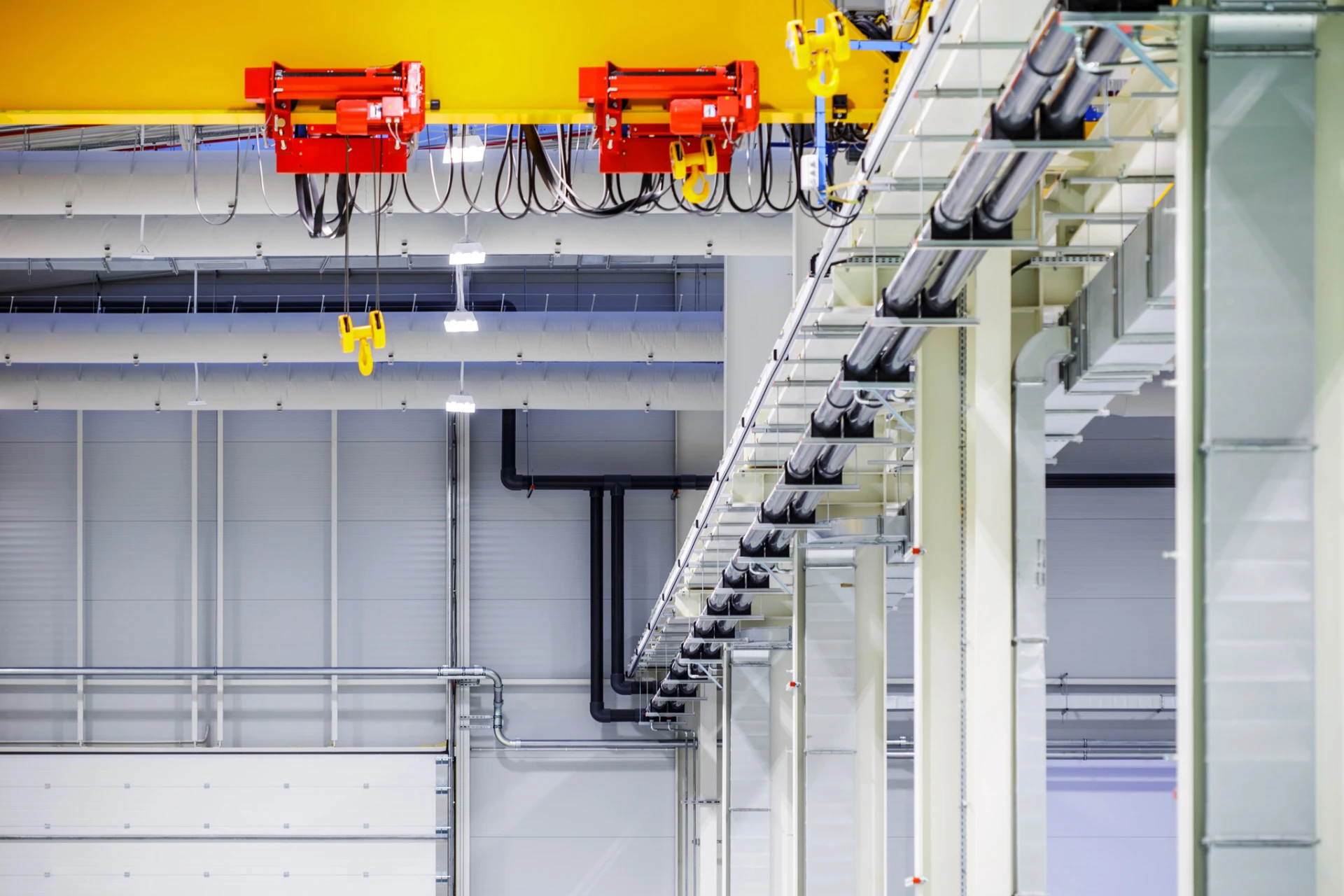

Industrial ConstructionAs part of the investment, a production building with an administration and office area was built. The structure of the main hall was made of prefabricated steel elements placed directly in a four-span construc- tion system, at a total weight of 280 tonnes. The building was covered with panels with a mineral wool core, and the roof of the building was equipped with a fall arrest system. A steel structure adjacent to the hall was built for the purposes of supply services. Inside the production hall, special anti-static concrete floors hardened with quartz stone were used. The hall was also equipped with a cold store and a paint shop with an individual mechanical ventilation system. Due to the specifics of the large-size element production, reinforced concrete technological ducts hidden in the floor in the amount of 552 linear meters were used to distribute specialist installations. The facility was equipped with electrical, telecommunication, ventilation and air- conditioning systems as well as a water supply, heat recovery from the compressors, and a sprinkler system designed and made to NFPA standard. The scope of works also included equipping the hall with six overhead cranes operating in tandem, each with a lifting capacity of 3.2 tonnes. The total usable area within the hall is 6,165 m2. An external infrastructure was also built with a 15,424 m2 hardened surface area. Before the development of the area around the investment began, the non-load bearing soil was replaced with over 25,000 m3 and drainage was fitted.

- Investor: JUPITER GROUP LLC

- Form: Design and build

- Value: 10 - 20 mln

- Project dates: February 2017 – November 2017